Wall Insulation

In this post we are looking specifically at Wall Insulation. Visit our Roof and Loft Insulation page to find out how to insulate your roof or loft.

Wall insulation standards

So what can be done?.

Party walls, the walls that separate one property from another, are in effect insulated from the outside by their neighbour. But external walls face the outside and in the winter when we have our heating on, approx one third of all heat lost in an uninsulated property is directly through the external walls. Bricks and blocks are not great at retaining heat, heat can pass straight through them. Insulating any external wall will stop or at least reduce the amount of heat that is lost through that wall.

Identify The Type Of Wall

Solid Brick Walls

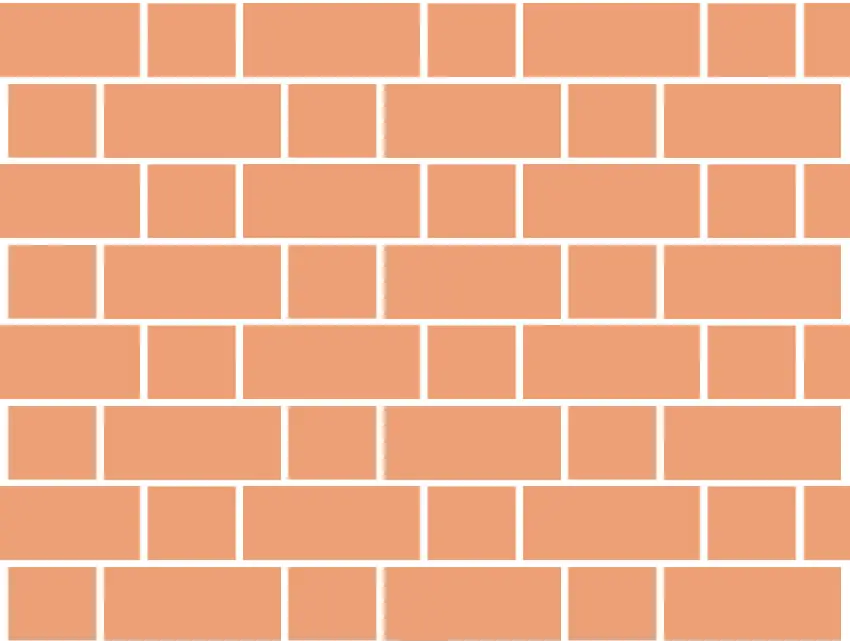

Generally solid brick walls are 260mm to 300mm thick and they consist of two rows of bricks built side by side with some bricks turned sideways to interlock the two rows. They are usually covered by a few centimetres of plaster on the inside of the wall and sometimes a few centimetres of render on the outside of the wall. If there is no render on the outside of the wall it’s easy to see the distinctive pattern of a solid brick wall – full length brick next to sideways brick next to full length brick and so on. In construction terminology, a full length brick is known as a ‘Stretcher’ and a brick laid sideways so it looks like half a brick is known as a ‘Header’.

Cavity Walls

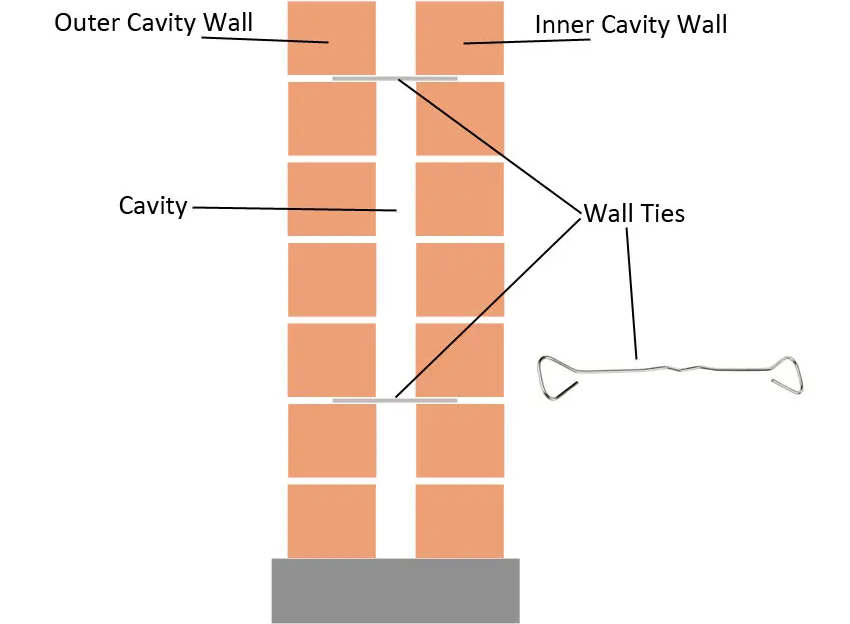

Cavity walls are usually 300mm+. Again there are two rows of bricks built side by side but this time there is a gap between the two rows. This is the cavity. All of the bricks and laid end to end, there are no sideways interlocking bricks. The rows are attached to each other using steel ‘wall ties’, securing the two walls together. The cavity between the two rows of bricks is full of air.

Filling the cavity with an appropriate insulating material provides a thermal barrier that prevents or at least reduces heat loss. This must be done properly though as it can lead to damp issues if not. The best place to measure the thickness of a wall is through a doorway or window. Remember to take into account any door or window frames.

Age can be a good indicator of how the walls in a property are built. If it’s in a suburban part of Brighton and Hove for example and it’s a Victorian (built 1837 to 1901), Regency (built 1811 to 1920) or Georgian property (built 1714 to 1837) it’s very likely to be solid brick. If it was built from 1920’s onwards, it is most likely to be a cavity wall built with bricks and in more recent years breeze blocks.

Bungaroosh

If you are in Brighton & Hove you’ve heard of Bungaroosh. Bungaroosh is classed as solid brick because it is solid, there are no cavities. It is actually a composite mixture of whole bricks, broken bricks, cobblestones, flint, pebbles, sand, bits of wood, basically anything that was lying around at the time the wall was built, mixed with a lime mortar and poured into shuttering or formwork to make walls. It is always plastered on the inside and rendered on the outside. It can dry out and crumble or subside if it gets wet and it has long been associated with damp issues. Many of Brighton’s Regency-style houses, crescents and terraces were built with Bungaroosh walls and finished with impressive rendered facades.

How Much Can You Save

Energy Bill Savings & Carbon Dioxide Savings Solid Wall

Energy Bill Savings & Carbon Dioxide Savings Cavity Wall

Installing Wall Insulation

Internal Wall Insulation

Internal wall insulation is a job for a professional builder / installer or a very good DIYer. It involves fixing insulation to every bit of the inside of an external wall, leaving no gaps so heat can’t escape. The existing wall will be completely covered by the insulation.

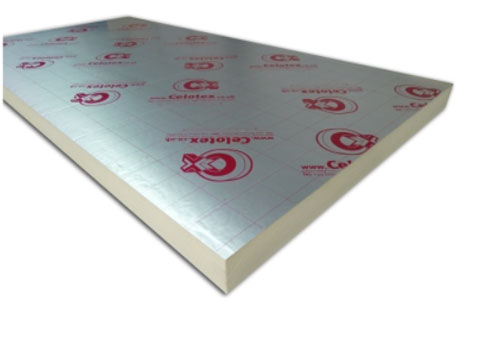

The insulation itself is usually very easy to handle. Rigid insulation boards are usually used for this type of insulation (e.g. Celotex / Kingspan), alternatively a metal or timber ‘stud’ frame is attached to the wall and filled in with mineral wool fibre or sheep’s wool. Mineral wool / sheep’s wool is less effective than rigid insulation boards.

Both types of insulation can be cut and shaped in any way to suit the area being insulated and fitted to ensure there are no gaps. Ideally the thickness of the insulation should be 60mm to 100mm at least. The newly insulated wall will then need plaster boarding and then plastering.

Insulating the wall will increase the thickness of the wall and make the room slightly smaller and this has implications for everything adjacent to the wall. Flooring, carpets, skirting, window and door frames, window sills, coving, radiators, wiring, plug sockets, pipework etc. It is likely that all of them would need to be altered to take into account the new thickness of the wall that they are touching or near. Insulating the inside of a wall can make it more difficult to fix heavy items like cupboards to the wall. There are special fixings available to allow for insulated walls.

It’s quite a lot of work and very disruptive in the room whilst its being done and hiring professionals can make it expensive. However it will significantly reduce the amount of heat that is lost through that wall and that means you will use less heat, save money on your heating bills and reduce the amount of climate changing pollution your heating system may produce.

External Wall Insulation

Fixing insulation to the outside of a property is definitely a job for a professional installer. Insulating an external wall involves fixing appropriate insulation panels to the entire wall and then covering the insulation with render, tiles, cladding etc to make it weather proof. The wall needs to be structurally sound and any existing damage to the outside of the wall should be repaired first, cracks in the brickwork etc, as once the work is done the original the wall face will no longer be accessible.

Obviously the installer will need easy access to the whole wall that you are insulating. You may need planning permission to fit external insulation as you are changing the way the front of the property looks, the new outside wall will sit proud of any attached properties either side of it that have not been insulated and depending on how you finish the wall, it may look different to how it looked before. Again the wall thickness changes and this could impact anything that touches the wall, e.g. window frames and sills, the eaves of the roof that overhang the existing wall etc.

Panels are initially glued to the wall and then securely fixed with metal fixings. The fixings need to be recessed into the insulation panels and then they should be filled with a thermal dowel cap to stop thermal bridging – heat passing through the fixings. The panels are easy to work with, very dense but light weight and very durable. The are non degrading, have a very low thermal conductivity and moisture absorption rate and once covered should be weatherproof.

External insulation will increase the lifespan of the brickwork as it will no longer be taking the brunt of the weather, it adds a level of sound proofing to the property and it can reduce or even stop condensation that forms on the inside of the property.

Cavity Wall Insulation

Cavity wall insulation is relatively straight forward in comparison to installing internal or external insulation but is definitely a job for an accredited and experienced professional due to the implications of doing it wrong. It is possible to install cavity wall insulation and external wall insulation on the same wall making it super efficient and significantly reducing the risk or damp issues that sometimes result from cavity insulation. The external wall insulation is weather proof so there should no way for moisture to make it through to the cavity.

If your house was built from the 1990’s onwards, the walls should already be insulated. Properties built from the 1920’s to 1990’s were most likely built with cavity walls with the cavity left empty. To fill an existing cavity you should hire a professional installer who is a member of one of the following organisations:

The National Insulation Association (NIA)

The Cavity Insulation Guarantee Agency (CIGA)

The British Board of Agrément (BBA)

The insulation should be guaranteed for 25 years by CIGA or through an independent insurance backed guarantee.

A professional installer should be able to drill test holes to tell you if the wall is suitable or if there is already insulation present. They will check the depth of the cavity, it needs to be at least 50mm wide and it needs to be clear of debris / rubble from when the walls were built. The walls need to be in good structural condition, not exposed to driving rain and the property can not be at risk of flooding. You will need to resolve any damp issues before cavity wall insulation is installed, you should speak to a damp expert for this.

It will take a professional installer a few hours working from the outside and there should be no mess. The installer will drill small holes in the outside wall and pump polystyrene beads into the cavity and then fill the holes. Polyurethane foam can also be used and this is a very good insulator but it’s not always suitable / possible and it’s more expensive. If there are issues with the cavity, e.g. the cavity isn’t a uniform 50mm across the whole wall, there is a risk of flooding etc, then foam is a better option.

It’s not possible to install cavity wall insulation in a part of a wall. If you live in a flat with an external wall that you share with adjacent flats, you would need to get agreement from your neighbours as the whole wall would need to be done at the same time.

Ventilation

Cavity walls were introduced to stop moisture from passing through brickwork from the outside of a property to the inside. Moisture that makes it through the outside bricks will run down the inside of the cavity wall and drain away. Filling the cavity bridges that gap so there is a risk that moisture could make it all the way through and you can end up with serious damp problems. There are lots of horror stories, particularly from the 1970’s and 80’s where inexperienced installers and cowboy builders created far more problems than they were trying to fix by not installing the insulation properly. Getting the ventilation right is key to a successful install. This might mean air bricks or wall vents, an experienced installer will be able to explain what is required for your property and take steps to ensure the property is still properly ventilated.